HVAC Bags and Assemblies

Flow Dry has serviced the automotive HVAC industry for 50 years. We are highly trusted by Tier 1’s and Tier 2’s with high quality standards.

The core of our business is our desiccant bags, assemblies and cartridges, which control moisture through molecular sieve beads.

We have recently brought to market two solid form desiccants that can also be leveraged in automotive HVAC systems: Polysorb and IDB.

Learn more about how to choose the right product for your system on our Automotive HVAC page

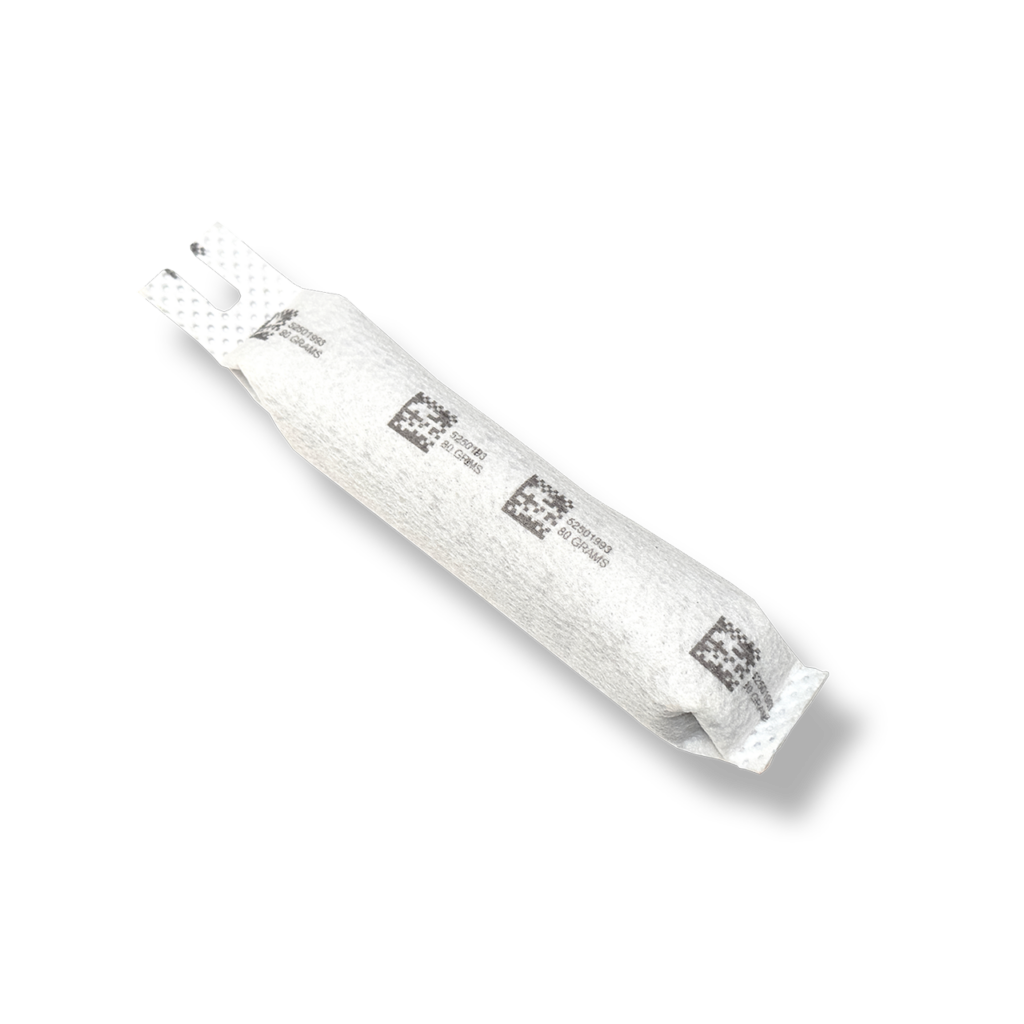

Bags

Our bags are our classic HVAC moisture management solution. We manufacture conventional bags for accumulators and saddle bags for receiver dryers.

Consisting of molecular sieve sealed in felt, to consistently yield a quality product, it is critical to source these raw materials from reliable suppliers with high standards. Due to our decades of experience and global footprint, we have strong relationships with premium suppliers across the world, resulting in a differentiated product for our customers.

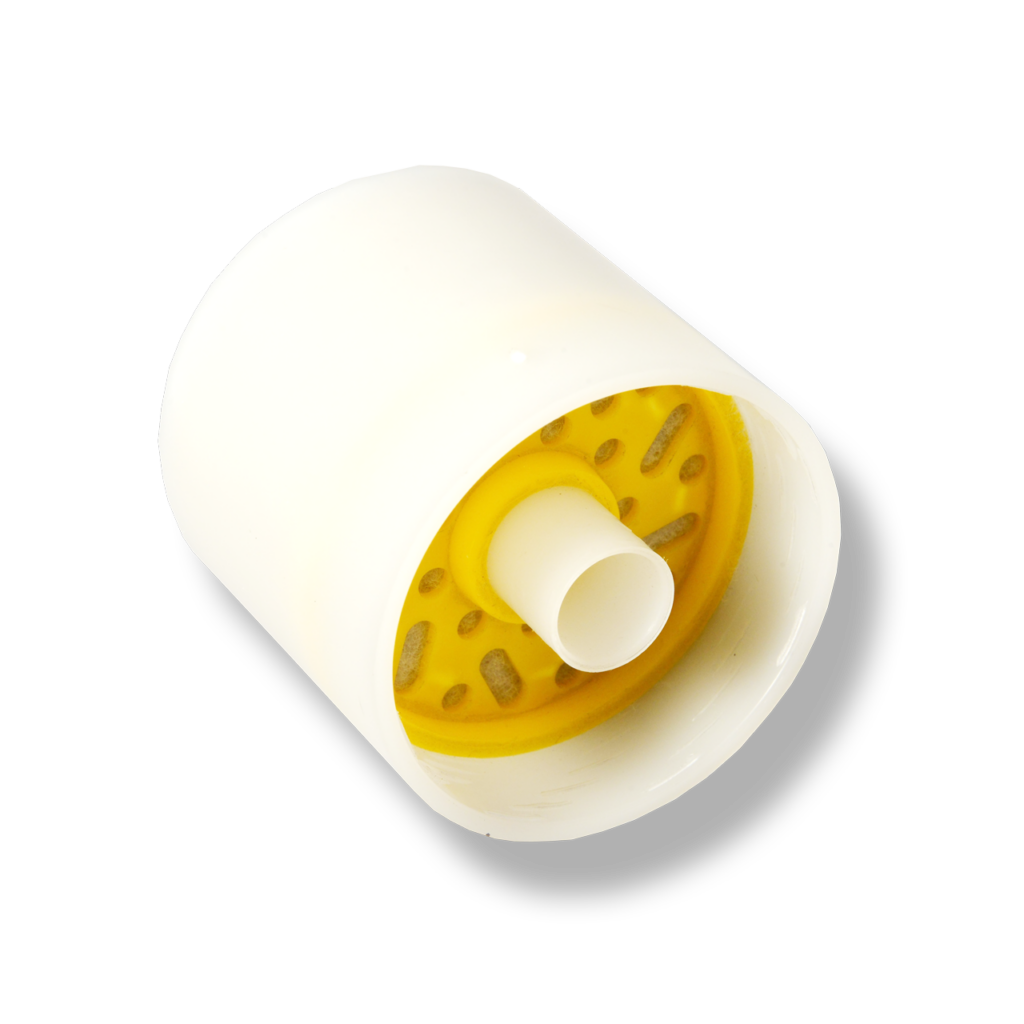

Assemblies

Our assemblies enable customers to install our bags into their HVAC systems more quickly, reducing fabrication time and line costs. We have the capabilities to manufacture not only bag holders, but also plugs and filters, resulting in a more advanced moisture control and flow management solution. We maintain injection molding operations in all our factories.

Cartridges

Pre assembled and sealed at our facilities, our cartridges can be installed in your HVAC receiver in one step, increasing the efficiency of customer assembly lines. They are easily held in place inside the receiver with simple, inexpensive methods, such as bead upsets or pal-nuts.

Due to our Lip-Lock® seal ring technology, the same cartridge can be leveraged in a variety of receiver can sizes, eliminating the need to purchase custom tooling for multiple programs. Since the cartridge comes pre-sealed, it can be exposed to moisture up to 10 times longer at your facility than a bag before exceeding moisture specifications.

We have the capability to insert fluorescent dye wafers into any of our classic HVAC desiccant products. When the HVAC system starts, the dye mixes and circulates with the refrigerant. In the event of a leak, the dye escapes with the refrigerant, making the point of the leak visible.Learn more about how this technology works from our partner Tracer Products

The Flow Dry Advantage

Advanced Manufacturing Close to the Point of Installation

We maintain IATF certified operations in the U.S., Hungary and China.

That means that, for the vast majority of customers, we can manufacture desiccant bags and cartridges on the same continent on which they will be sealed into an air conditioning system, reducing the risk that bags will absorb moisture during transport, which would make them useless.

This leaves our customers less vulnerable to quality risks, enabling them to eliminate incoming inspections and reduce scrap.

Each of our facilities has both desiccant bag capabilities and advanced injection molding capabilities.

Strong supplier relationships

Due to our years of experience and production volumes, we have extremely strong supplier relationships.

In 2022, when the leading supplier of automotive molecular sieve in North America shuttered operations, we supported our automotive customers in running chemical compatibility testing on alternative molecular sieves from our broader supply network, then transitioning supply. We did this at the peak of the shipping container shortage without shutting a single customer line down or expediting any material. The elimination of this one strain of sieve from the market could have been the second chip shortage because this strain was so ubiquitous in the U.S. automotive industry – but it was not because we acted.

Integrate Flow Dry HVAC Bags Into Your Product

Our product team can help you create a component that fits your design